|

|

11/22/2008 |

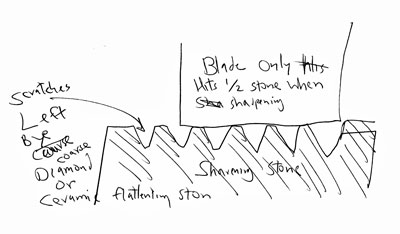

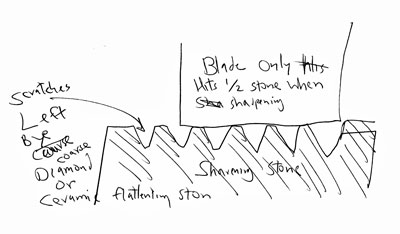

For years my standard method of flattening waterstones was to take soaked stones and rub them with a diamond stone or a Flattening stone. Either method works fine but I was always taught that fine stones (5K and up) should really be flattened using a finer grit flattener. The reason for this is that the coarse flattening stones leave deep (in proportion to the grit of the stone) scratches in the finishing stones and when you sharpen you just ride on the peaks of the stone and consequently you only use half the actual surface of the stone. You also effectively put more pressure on the parts of the stone you do use - and that makes the stone cut coarser than it should (just like retexturing a tormak). For years my standard method of flattening waterstones was to take soaked stones and rub them with a diamond stone or a Flattening stone. Either method works fine but I was always taught that fine stones (5K and up) should really be flattened using a finer grit flattener. The reason for this is that the coarse flattening stones leave deep (in proportion to the grit of the stone) scratches in the finishing stones and when you sharpen you just ride on the peaks of the stone and consequently you only use half the actual surface of the stone. You also effectively put more pressure on the parts of the stone you do use - and that makes the stone cut coarser than it should (just like retexturing a tormak).

The whole point of using a flattening plate or a coarse diamond stone is speed, but if I end up with a slow cutting coarser finishing stone what's the advantage? So What I would do - if I wasn't lazy is to first get the stone flat  with the flattening plate and then do a pass or two with some 220 or so grit sandpaper. Since I am not flattening anymore - just conditioning the surface, the sandpaper works quickly - but I still need to have sandpaper. with the flattening plate and then do a pass or two with some 220 or so grit sandpaper. Since I am not flattening anymore - just conditioning the surface, the sandpaper works quickly - but I still need to have sandpaper.

Some manufacturers have tried to get around this problem by offering smoother diamond stones - but they flatten too slow for my tastes.

Recently, instead of sandpaper after I flatten with the flattening plate I rub my finest stone against the second finest. Then the second finest against the third, and so on until I do the series. Then all the stones get washed thoroughly to get rid of any contamination and I am done. No sandpaper required.

This works great because the stones are flat to begin with from the flattening stone and the few strokes don't effect flatness. Since I am going from fine to coarse each stone will be contaminated by at the most one finer grit.

The end result is that my stones cut faster than ever before and that saves a lot of time. The picture above shows a freshly hollow ground chisel and a 10k Chosera stone after one stroke on the stone.

Here is a link to the Norton flattening stone.

We also stock some giant Naniwa flattening stones.

BTW there is no need to decide if I am right or wrong based on this blog entry.

Try it yourself and let me know what happens. I could be just my imagination but I don't think it is.

|

Join the conversation |

|

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

For years my standard method of flattening waterstones was to take soaked stones and rub them with a diamond stone or a

For years my standard method of flattening waterstones was to take soaked stones and rub them with a diamond stone or a  with the flattening plate and then do a pass or two with some 220 or so grit sandpaper. Since I am not flattening anymore - just conditioning the surface, the sandpaper works quickly - but I still need to have sandpaper.

with the flattening plate and then do a pass or two with some 220 or so grit sandpaper. Since I am not flattening anymore - just conditioning the surface, the sandpaper works quickly - but I still need to have sandpaper.

Comes in a range of grits up to 220, and the great thing is the waterstone slurry just drops through. And this is easily the cheapest method as well as being quick and effective.

By having the mesh always beside the stones on the slab, I can give the stones a few swipes regularly and the stones do not get out of flat. Because the slurry drops through - and it is easy to wash the mesh, there is no contamination of the sanding material, and no random bits of coarse stone getting into the fine stones.

Derek

Recently I had to deglaze a Shapton #120. I used a coarse diamond stone (#325). It smoothed the surface far too well. Presumably the harder diamond was shearing the tops off the alox crystals. Next effort worked much better: #36 SiC grains on glass (following detailed instructions from Stu Tierney from ToolsfromJapan.com ).